The project

The REUSE project seeks to overcome several challenges in existing CO2 utilization pathways:

Limited use of RDF in biomass blends restricts fuel efficiency.

Inconsistent flue gas composition complicates emissions control.

Tar-abatement catalysts are easily poisoned, reducing effectiveness.

Lack of research on solvents for RPB systems with CA or CO2R.

Focus on low productivity systems hinders industrial scaling.

Inadequate catalyst performance and lack of corrosion studies.

Limited understanding of BCS, RPB, and CO2R interactions.

Lack of model-based investigations for scaling up systems.

To address these challenges, the REUSE project will employ several innovative methods:

Test various biomass and RDF blends to optimize fuel use.

Explore sterically hindered and phase-change solvents for CO2 capture.

Create comprehensive models to optimize integrated systems.

Use DoE and PoE to minimize flue gas variability.

Develope functionalized carbon surfaces and tin-based catalysts for CO2R.

Introduce new Fe-Mn catalysts for better long-term performance.

Establish a pilot plant to evaluate BCS-RPB-CO2R interactions.

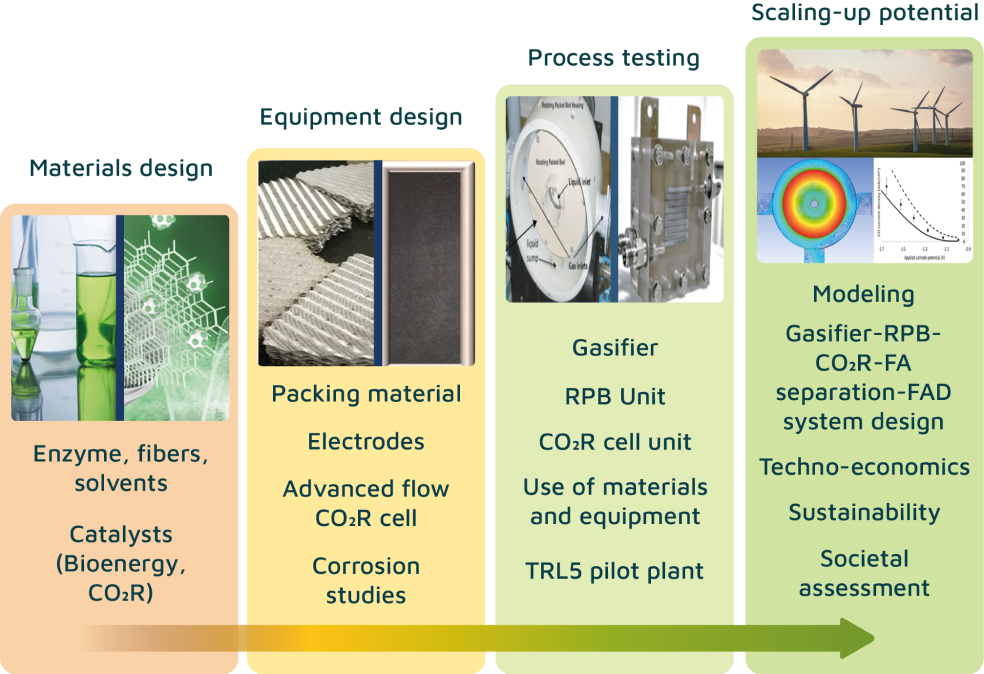

Overview of REUSE concept and activities.

- RPB: Rotating Packed Bed

- COR: CO, reduction

- FA: Formic Acid

- FAD: Formic Acid Dehydrogenation

Biomass Blends

Residual Forest Biomass Blends

Mainly consisting of eucalyptus, pine, and some oak.

Refuse Derived Fuel

This includes municipal solid waste from Aveiro and nearby areas.

Wood Pellets

A common biomass fuel source.

Timber and Agricultural Residues

Includes waste from vineyard pruning, fruit tree trimming, and olive groves.